Quality Assurance For The Production of

High-Quality Monitor

Kaidi’s advanced manufacturing process, rigorous quality assurance measures, and adherence to industry standards ensure high quality, precision, and durability of your OEM ODM Monitor.

- ISO 9001:2015 certified

- 10 + material inspection processes

- 20 + product inspection standard

How Monitor Guarantees Superior Quality

- Well-Vetted Suppliers

- Quality Materials

- Professional Designing

- Strong Manufacturing

- Rigorous Inspection

We take great care in the selection process of our suppliers. We understand the critical role they play in our operations, and therefore, we dedicate significant effort to ensure that we collaborate with the best partners in the industry.

We place a strong emphasis on the quality of materials we use. Each batch of materials that arrives undergoes a meticulous testing process, allowing us to distinguish top-grade materials from those of inferior quality.

Our team has many professional LED TV engineers who are dedicated to reviewing and refining your project ideas. They possess the knowledge and expertise to assess the feasibility of your designs and determine the most effective approach for creating the final TV.

We have 300 well-trained workers, mature quality management system, 16000 square meters of production workshop, strong production capacity to ensure timely delivery.

We prioritize rigorous inspections throughout our production process. Our dedicated Quality Control (QC) employees conduct a comprehensive series of inspections, including material inspection, processing inspection, and tv finished product inspection.

ISO Certifications &

Quality Reports

We have gone the extra mile to ensure that our operations align with the highest industry standards. To demonstrate our commitment to quality and excellence, we have proactively pursued and obtained recognized certifications from reputable organizations.

- ISO 9001:2015

- amfori Social Audit - Manufacturing

- UL-Factory Quality Audit

Specific Practices for Quality Assurance

Pre-production

Technical assessment

Technical assessment

Material verification

Material verification

In-production

On-site inspection system

On-site inspection system

In-process quality control

In-process quality control

Final production

Inspection report

Inspection report

Packaging

Packaging

Service FAQs

Every question has an answer

Are you a Trading Company or Manufacturer?

Can you print any logo for customer?

Do you offer the free samples?

How long does sample take?

How long does normal order take?

What is your advantage?

Can I make my customize logo and packaging or private label?

Can you do design for my ideas or drawing?

Our Latest News

What is the difference between LED and LCD liquid crystal monitors?

there is a heated discussion about whether to choose LED gaming display or LCD gaming display With the popularity of various technologies in recent years, it is recognized that a powerful display is essential for gamers who want a satisfying gaming experience. Nowadays, there is a heated discussion about whether to choose LED gaming display […]

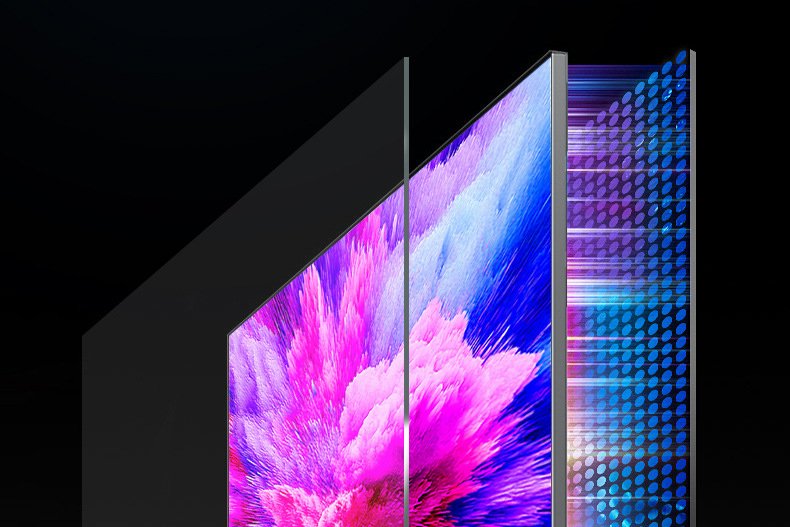

The composition of LED Monitor.

LCD display is a display that uses liquid crystal as the material. Liquid crystal is an organic compound that lies between solid and liquid. When heated, it becomes a transparent liquid, and when cooled, it becomes a crystalline cloudy solid. Under the action of an electric field, the arrangement of liquid crystal molecules will change, […]